The company's design and implementation of the phosphorus removal system project, are equipped with the following several imported European high-pressure phosphorus removal pumps for customers to choose:

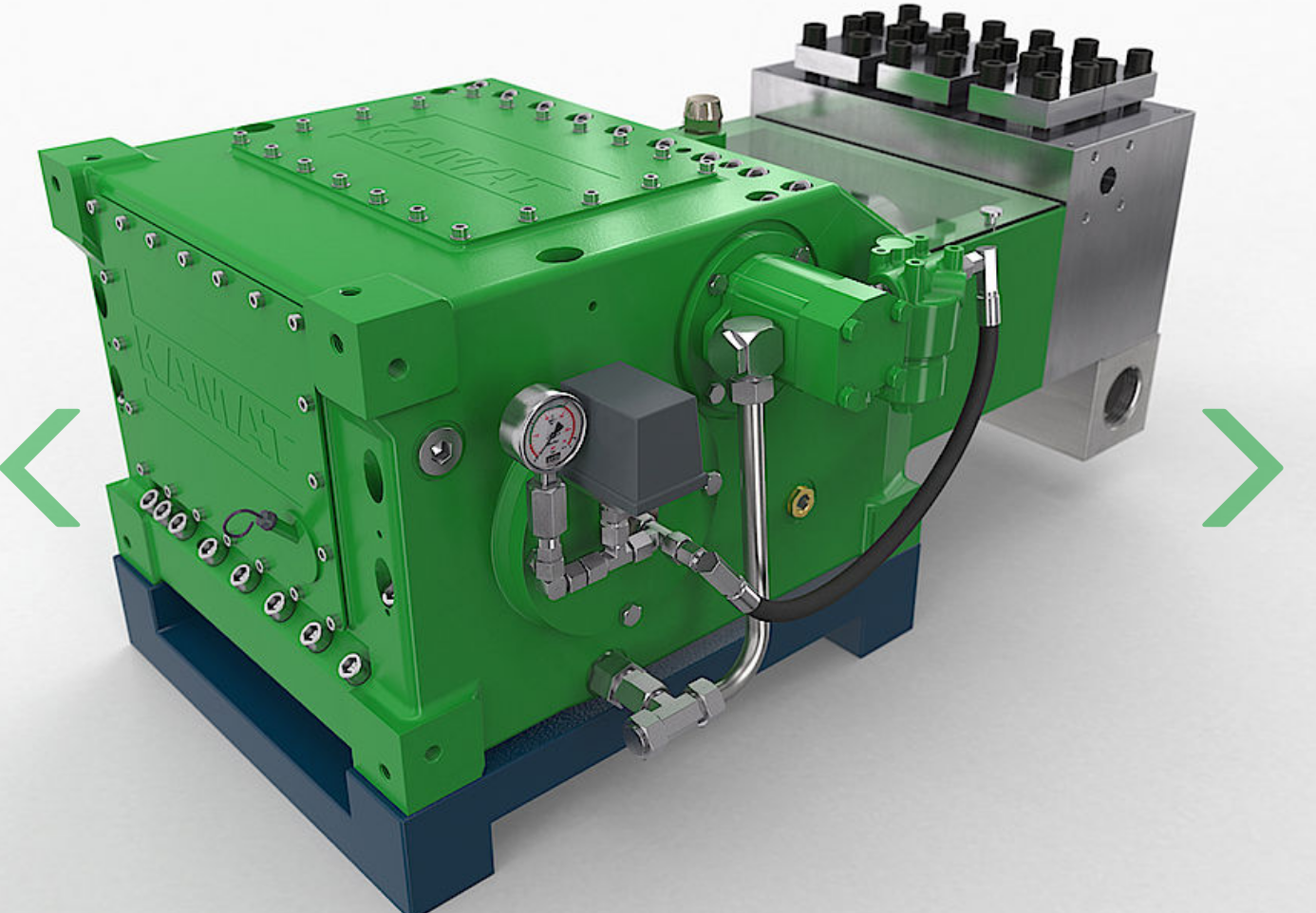

1. Authority in the field of high pressure - Germany KAMAT Pump Co., Ltd.

- Brand Overview:

Germany KAMAT is the authority in the field of high pressure. As a subsidiary of Myers-Europe, it was founded in Essen in 1974. In 1979, Mr. Sprakel took over as president. In 1982, he took over the Messrs high-voltage equipment factory founded in 1960 in WITTEN, 1984. In the merger of the two factories, KAMAT Pump Co., Ltd. was established. KAMAT is a 100% family private company with approximately 80% of its products exported to more than 50 countries and regions in the world and more than 40 agents worldwide. Its products are widely used in steel, petroleum, chemical, marine, automotive, power plants, non-woven, concrete and other fields.

- main products:

a) High-pressure piston pump — rated input power of single pump from 45 to 550 kW; maximum working pressure of 3000 bar at flow rate of 17 L/min; working pressure of 120 bar at maximum flow rate of 2400 L/min.

The high-pressure pump is supplied with an input power of up to 550 kW, a flow rate of up to 2363 L/min, and an output pressure of up to 3,200 bar.

The drive gear shaft and the crankshaft have a common lubrication chamber. The supply of oil is achieved by a pressure oil supply system driven by a drive gear shaft, including oil pressure and oil temperature monitoring systems.

The pump head is made of special steel and can be operated in corrosive media. The aspiration valve and the drain valve have direct passages that are exchanged between the upper and lower sides, and the replacement does not require disassembly of the plunger. The plunger is made of oxidized ceramic to ensure its long continuous running time and longevity. Different working pressures and work efficiency can be obtained by changing different accessories. The plunger is driven by a forged crankshaft supported by a cylindrical roller bearing. The transmission of the helical gear ensures low noise and high efficiency operation of the crankshaft. Inspection and replacement of the plunger and pump body does not require the use of any special tools, and does not require disassembly and reassembly of the pump head.

Available selection table:

b) high pressure system and pump set - input mileage up to 1400kW; PLC control system; electric or diesel engine;

c) Various valves - pressure regulating valves, pressure relief valves, control valves, safety valves

d) Accessories - flat washers, spray guns, 3D nozzles, nozzles of all types

- Application area:

·Pipe cleaning

·Concrete structure repair and paint cleaning

·Heat exchanger cleaning

· Paint cleaning on the grid

·Paint cleaning in the printing industry

·Steel surface derusting and cleaning

· Cleaning of various containers

·Steel industry descaling

·Filter cleaning

·As a reverse osmosis pump (desalination)

·Mine production pump

2. Germany WOMA

- Brand Overview:

Germany WOMA is one of the world's leading manufacturers of high-pressure water jet equipment. WOMA was founded in 1962 in Duisburg, Germany. As an innovation leader represented by quality, efficiency and reliability, WOMA has achieved rapid success and made WOMA world famous. For over forty years, WOMA's high-pressure water jet technology has been widely used in all areas of modern industry. The high-pressure water jet system developed by WOMA solves a series of problems in the field of maintenance, industrial washing and purification. It is used in the following applications: surface treatment, pipe cleaning and tube cleaning, container cleaning, cutting and separation. .

- WOMA high pressure pump features:

Woma

WOMA designs and manufactures high-pressure piston pumps with hand-operated or mechanically controlled water tools. The machine is driven by a motor or diesel engine with a maximum power of 780 kW, a maximum flow of 1680 L/min and a maximum pressure of 3000 bar.

Forced lubrication with hydraulic pressure

Adjustable gear ratio

The pump head adopts a building block structure

Maintenance free plunger seal

.long lasting

High volumetric efficiency

Easy to repair

Optional model

Womatyp

3. Italy INOXIHP

- Brand Overview:

Founded in 1977, INOXIHP S.r.l. is a professional supplier of high pressure water equipment for the world's most famous heavy duty continuous industrial sector. INOXIHP high-pressure pneumatic control valve has rich experience and high-quality performance to ensure the customer's specific conditions, adhering to ISO9001 quality certification standards and ATEX explosion-proof certification and other international standards. INOXIHP high-pressure pneumatic control valve has won praises from customers for its primary and secondary descaling systems for various steel rolling, precision manufacturing technology, mature design and excellent after-sales service guarantee.

INOXIHP high pressure pneumatic control valves serve the world's most famous steel mills, metallurgy, mining and manufacturing.

- main products:

High pressure pneumatic control valve, horizontal high pressure seven plunger pump, INOXIHP horizontal high pressure five piston pump, horizontal high pressure three plunger pump, pump unit, two-position two-way pneumatic control valve, two three-way pneumatic control valve, INOXIHP Water switch valve, INOXIHP balance stop valve, INOXIHP proportional valve, INOXIHP check valve, INOXIHP oil switch valve, etc.

Optional model:

Inoxhiptyp

Type: 2nd or 2nd tee

Series: VDS

Fluid: water and HFA fluid.

Working pressure: 250 bar or 315 bar.

Function: normally closed or normally open

Working temperature: +2-+60°C

Path: 20-200mm

Electrical parameters: 24VDC-110/22V

Pneumatic supply: lubricating compressed air 5-7bar

Material: spool stainless steel, valve body carbon steel

Accessories: position switch, flange, base

Features: High reliability and low pressure loss in heavy duty continuous work.

Uses: mainly used in the descaling industry.