Automatic assembly purification type metallographic sample cutting machine

Overview

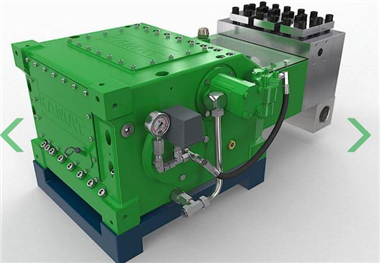

PKQG-II automatic assembly purification type metallographic sample cutting machine is a fully automated equipment that combines cutting, purification and cooling. Adopting Siemens programmable controller, it has very high reliability and powerful control ability; it adopts touch screen in human-computer interaction; it adopts high-precision stepping motor in control. It is suitable for cutting samples of various metal and non-metal materials in order to observe metallographic and petrographic structures of materials. The cutting process of the machine is automatic, low noise, easy to operate, safe and reliable, and it is one of the important equipments for making solid material samples in modern laboratories.

Equipment structure

This machine is composed of cutting system, purification system, cooling system, lighting system, cleaning system and so on.

The workbench is completely covered by a retractable cylinder guard. The front of the guard is an oversized viewing window. The high-brightness illumination system allows the operator to keep track of the cutting process.

The vise table for pneumatically gripping the grooved jaws is capable of cutting workpieces of various sizes and sizes.

The high-precision stepper motor cutting rod pushes the cutting workpiece to automatically adjust the cutting speed, which makes it very easy to cut large workpieces.

The fully enclosed design of the super purification system can quickly deal with the fumes, dust and sparks generated by the grinding wheel.

The cleaning large-scale metallographic cutting system installation grinding wheel cutting piece can also be equipped with a metal cutting gear blade. The metal blade is cut with a super-cooling system so that the workpiece does not burn when cut.

The cooling water tank is placed inside the base of the equipment, and there is a filter bag inside the water tank for collecting waste debris.

The speed control system can control the cutting speed according to the cutting material.

The large-scale metallographic cutting equipment for cleaning and cleaning is equipped with a safety switch. When the door system is closed, the cutting system and the explosion-proof shield can be activated to ensure the safety of the operator.

Main Specifications

First, the power supply: 380V (three-phase)

Second, the frequency conversion motor power: 11KW

Third, the purification system processing capacity: 3500m3 / H,

Fourth, the fan motor power: 7.5kw

Five, grinding wheel specifications: 400 × 3.0 × 32, 400 × 3.2 × 32,

Sixth, the maximum cutting diameter: Φ120mm

Seven, cutting frequency control: 300~5000 rev / min, wide cutting range

Eight, cutting speed can be adjusted within 0.005-10mm / s

Nine, 680mm × 1030mm large cutting room

Ten, three different cutting modes: chopping cutting, pulse cutting, sweeping (Note: for different materials, different diameters, different hardness)

Eleven, cutting frequency control: 300~5000 rev / min, wide cutting range

Twelve, three-axis linkage, the maximum distance of the X-axis is 200mm, the maximum distance of the Y-axis is 300mm, and the maximum distance of the Z-axis is 240mm. The moving speed can be adjusted within 0-10mm/s, and the accuracy of the moving distance can reach ±0.005mm.

Thirteen, 120 liters of circulating cooling with magnetic filter and outlet filter

XIV, HMI human machine interface

Fifteen, the cutting process automation

Sixteen, workbench size: 450mm × 420mm

Seventeen, the whole machine size: 1500mm × 1500mm × 2500mm (length × width × height)

This site supports multi-terminal browsing

This site supports multi-terminal browsing